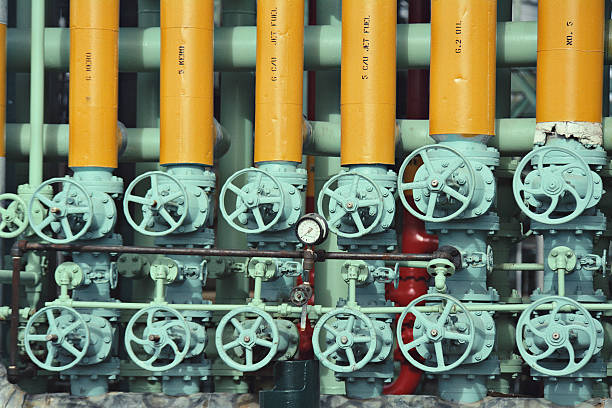

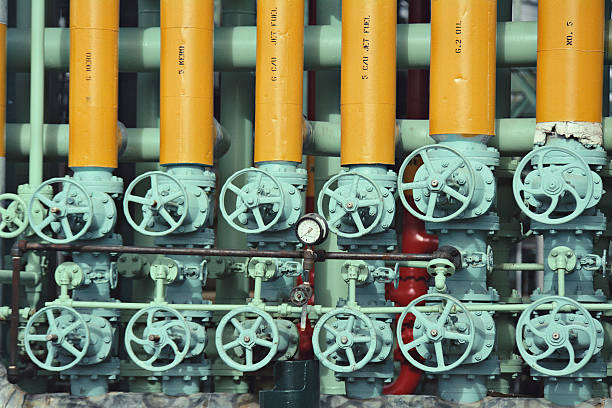

The lined butterfly valves would be found to have discovered numerous applications within the industry, its very design could be observed as featuring a disc that could be rotated with respect to a fulcrum in order to regulate the flow of fluid. The valve’s capability at opening as well as closing in the fast manner, along with minimal flow hindrance, is construed to be almost perfect option in connection with managing the rates of flow and that too with regard to the pipelines having fairly large diameter.

Erosion and wear

The fundamental advantage in this relation is that the lined butterfly valve is highly effective at controlling the flow of greatly corrosive fluids, for instance the acids in addition to alkalis, and this in the absence of any suffrage from the erosion as well as the wear. This happens because of the presence of the internal components encompassing the disc, the shaft on top of multiple parts, all these would be seen lined up with the greatly resistant element, the example being PTFE or the PVDF.

Lower risk

The lined water valves is regarded as greatly dependable, thanks to the simple design as well as the construction of theirs. Unlike the remaining valve types, the butterfly valves are loaded with fewer components which lead to reduced risk pertaining to mechanical failure. This lower risk could be translated into ease of operation in addition to maintenance, not-withstanding the industrial environs of hard sort. Another advantage regarding the lined butterfly valve has been that it may be employed in order to carry out regulation pertaining to the flow of the fluids in either of the directions.

Greatly reliable

The lined butterfly valve is generally used with regard to the applications wherein the direction of flow could vary frequently, for instance within the pipeline nexuses or the plants for chemical processing. The valve has been referred to as the versatile valve that has been employed in connection with broad range regarding the industrial applications. The lined butterflies are generally regarded as greatly reliable; it is owing to the design of simple category as well as the element of construction.

Defining “lined”

The term of “lined” denoted the fact that valve’s disc in addition to the supplementary internally placed components are lined in connection with the corrosion-resistant element, for instance PTFE (polytetrafluroethylene) or the very PVDF (polyvinyllidene). The purpose with regard to the lining projects is to accord protection to the vey valve against the corrosive substances which could be present within the already mentioned fluid that could be in the process of getting transported through the medium of pipeline.

Versatile valve

The robust construction pertaining to the lined butterfly valve have been referred to as versatile in addition to being reliable substitute and this in relation to applying control over the movement of the corrosive fluids with regard to the applications within the industry.